Designed and built in the UK, The HeatForm Tidal and Wave pool covers are a high end, slatted cover system engineered to the most exacting standard and designed with the highest quality components.

A decent quality slatted pool cover provides multiple benefits; reduced evaporation, additional thermal insulation and solar heat gains as well as reducing manual and chamical maintenance. We believe a cover is the icing on the cake of any pool project and as a prominent piece of kit, it should not only be efficient and robust but also look good. HeatForm slatted covers are modern and sleak in appearance and available in a variety of colours.

In-Pool Cover Options

HF Tidal Cave

HF Tidal Classic

HF Tidal Bench

HF Tidal Beach

In-Pool Covers

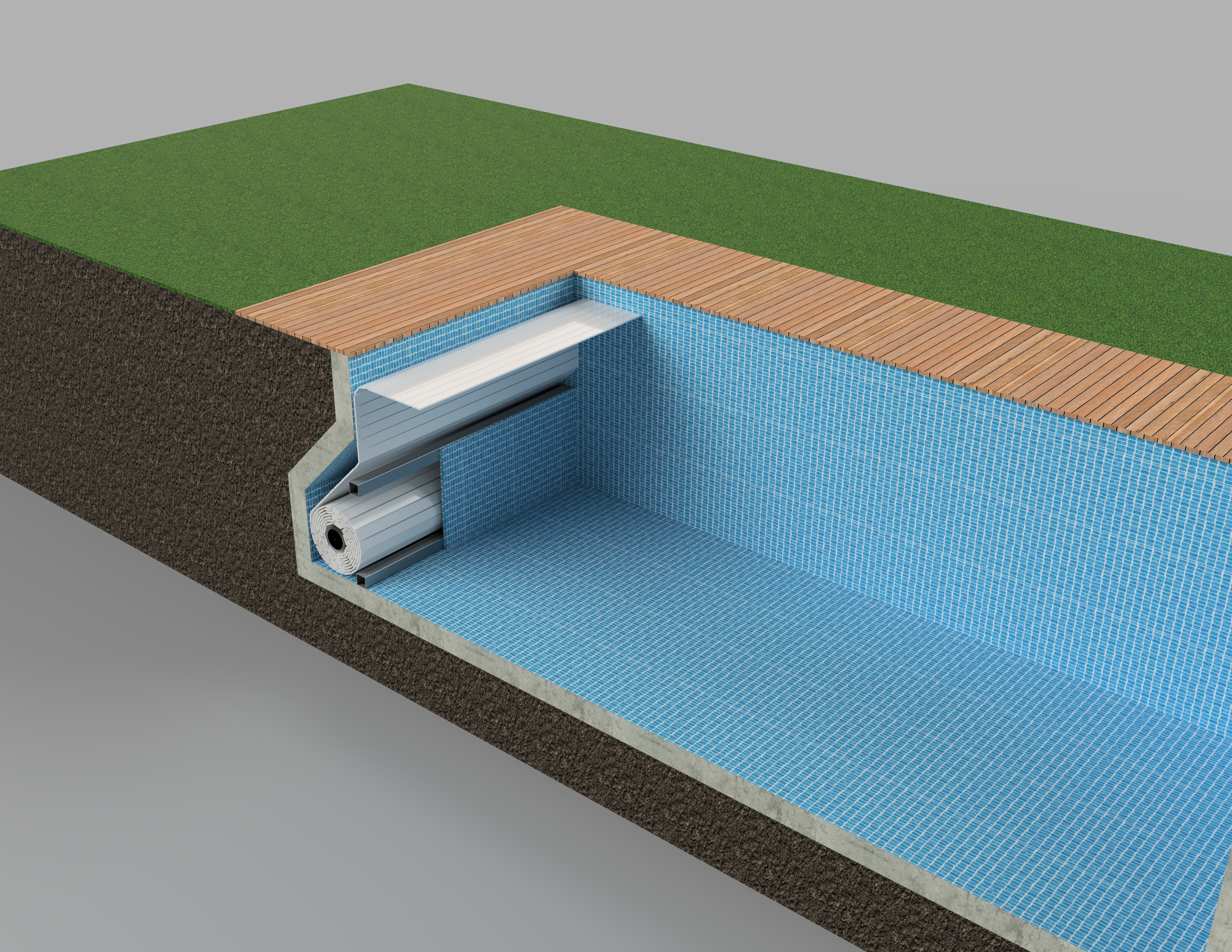

HF Tidal Letterbox with top support

In this configuration, the cover is concealed in a wet pit located behind a vanity wall. The top support is available for both wooden decking or stainless steel trays designed for patios. The cover system is accessible from the top to allow for easy maintenance and cleaning.

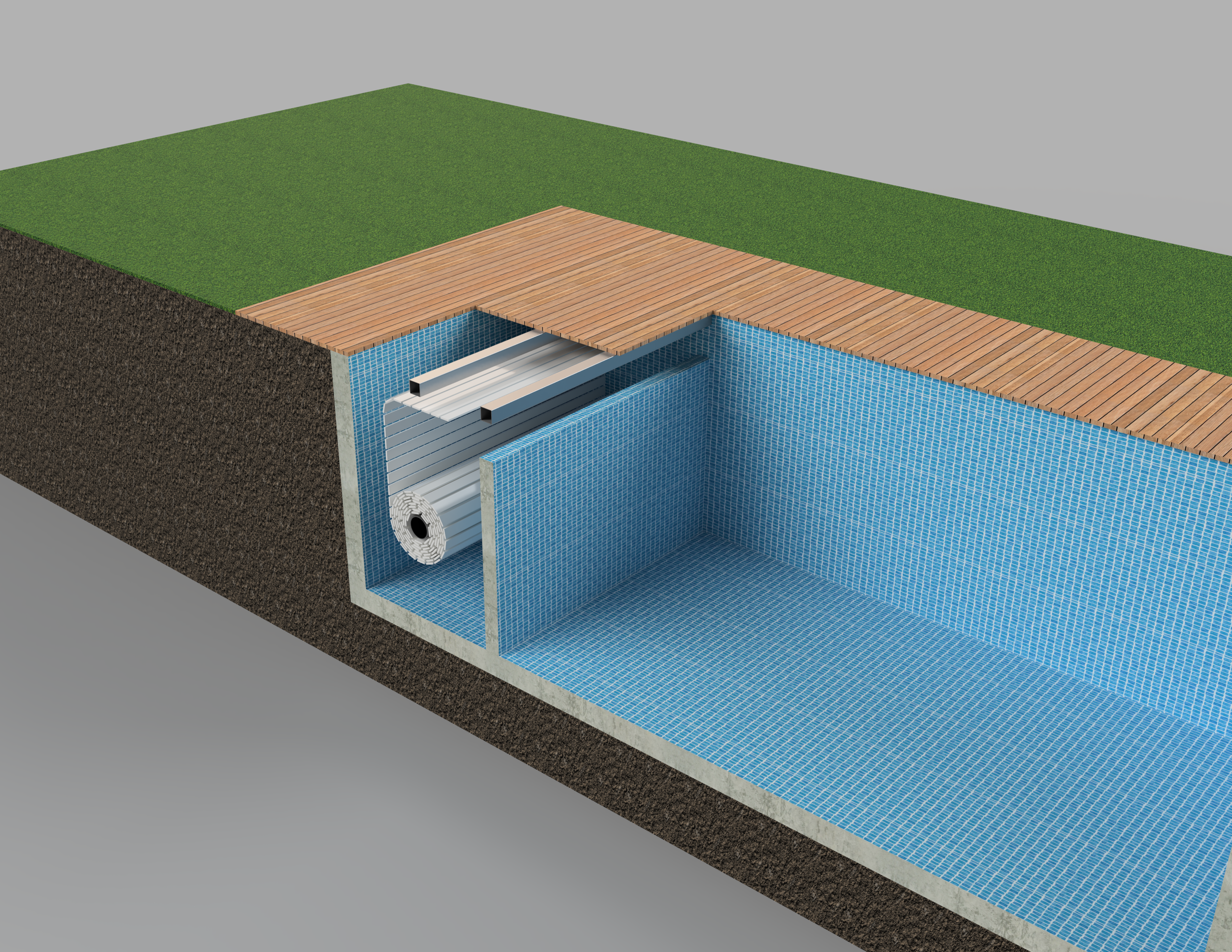

HF Tidal Beach Entry with PVC lid supports

This configuration allows for the submerged drive system to be installed when a purpose-built cover pit has not been designed into an existing or new pool. HeatForm covers modular design allows for a made-to-measure bench height. The cover panels can be lined to match your choice of pool liner.

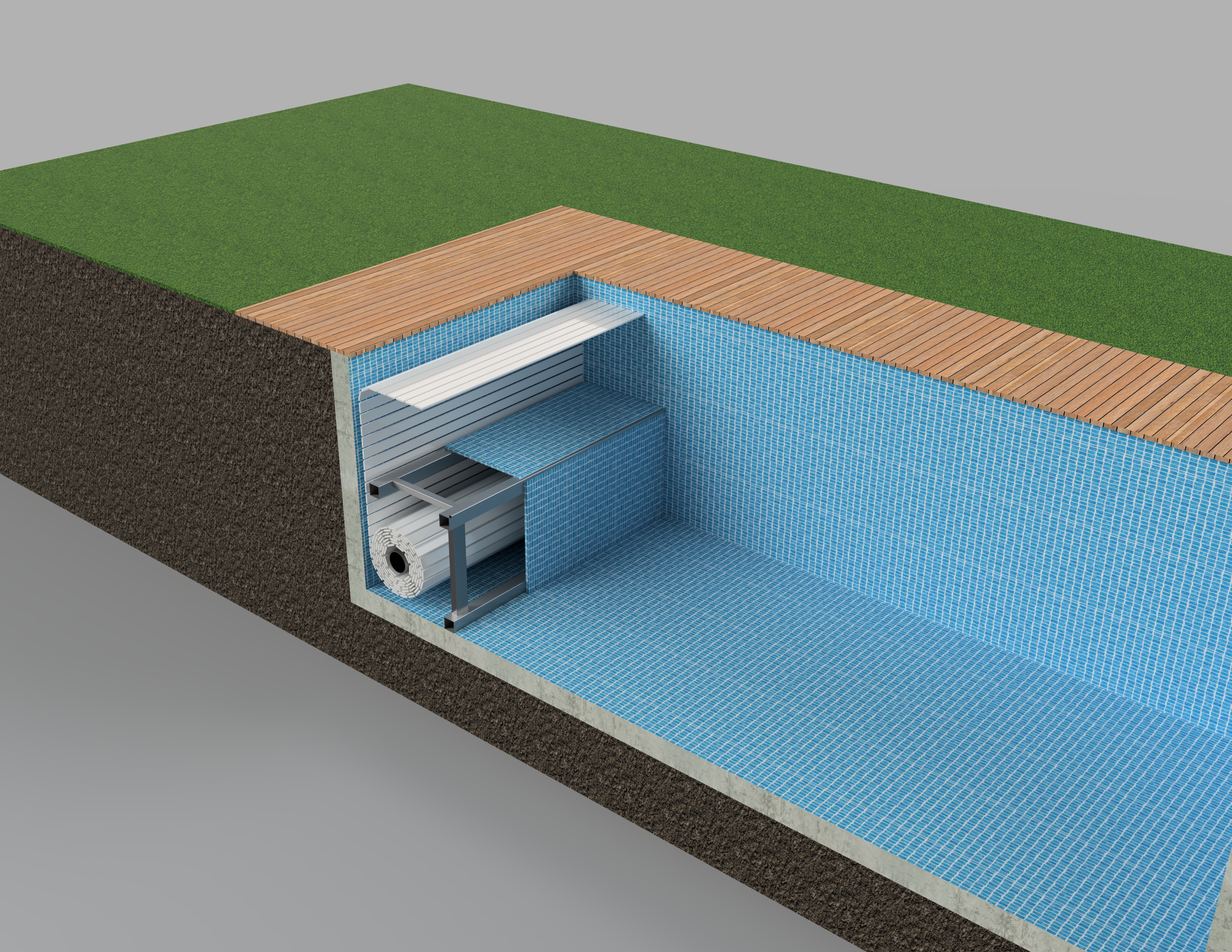

HF Tidal Bench system

This configuration allows for the submerged drive system to be installed in the bottom of the pool always retaining full access to the cover roller.

HF Tidal Cave Niche with PVC front wall

This configuration allows for the submerged drive system to be installed in the bottom of the pool in a niche built into the pool wall and retains full access to the cover roller via a front mounted PVC or composite panel which can be lined.

In-Pool Cover System

Following over 15 years of service in the field, the in-roller motor, used by HeatForm, has proven to be extremely reliable and efficient. With its clever use of nitrogen rather than resin to waterproof the mechanical components, it continues to be at the front of the market for innovation.

As the motor is fitted directly into the cover roller, there are no moving parts housed outside of the pool, ensuring minimum space requirements outside of the pool perimeter. The roller itself is immersed in the pool and supported by bracketry on both sides bolted to the pool structure. The cable from the motor passes through the pool shell and is covered in a plastic sleeve for additional protection.

The fully automated cover system is operated simply using a key switch or remote control. The motor comes in 250Nm and 500Nm torque variations, allowing for a wide range of pool sizes and depths and is provided with a 5 year manufacturer warranty.

The Wave

The Wave was born out of a desire to create a pool cover which was not only robust and reliable but also looked good. We wanted to create something which finished the pool off nicely but didn’t distract from the overall aesthetic. A finishing touch, a final flourish, if you will. The options for integrated lights and music bring an element of playfulness and, as with all our HeatForm products, the solar option offers cost savings and energy efficiency.

Fully automatic with remote control

Solar and Electric options

Integrated colour LED

Option for integrated LED in both stands

In-roller motor

Aluminium roller

Sleek and simple design

End stands Available in Anthracite, Light Grey, Sand and White

For pools up to 6m x 12m

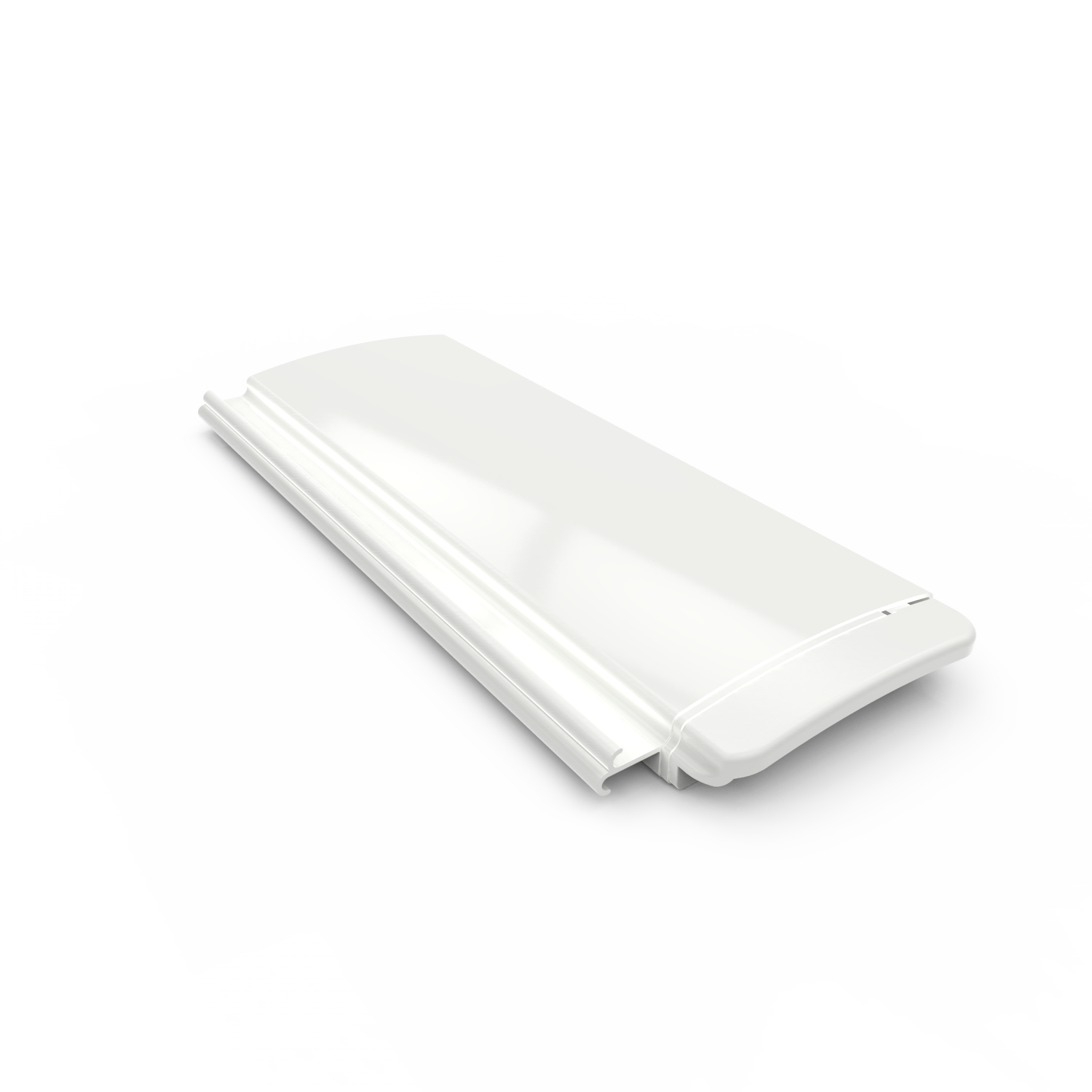

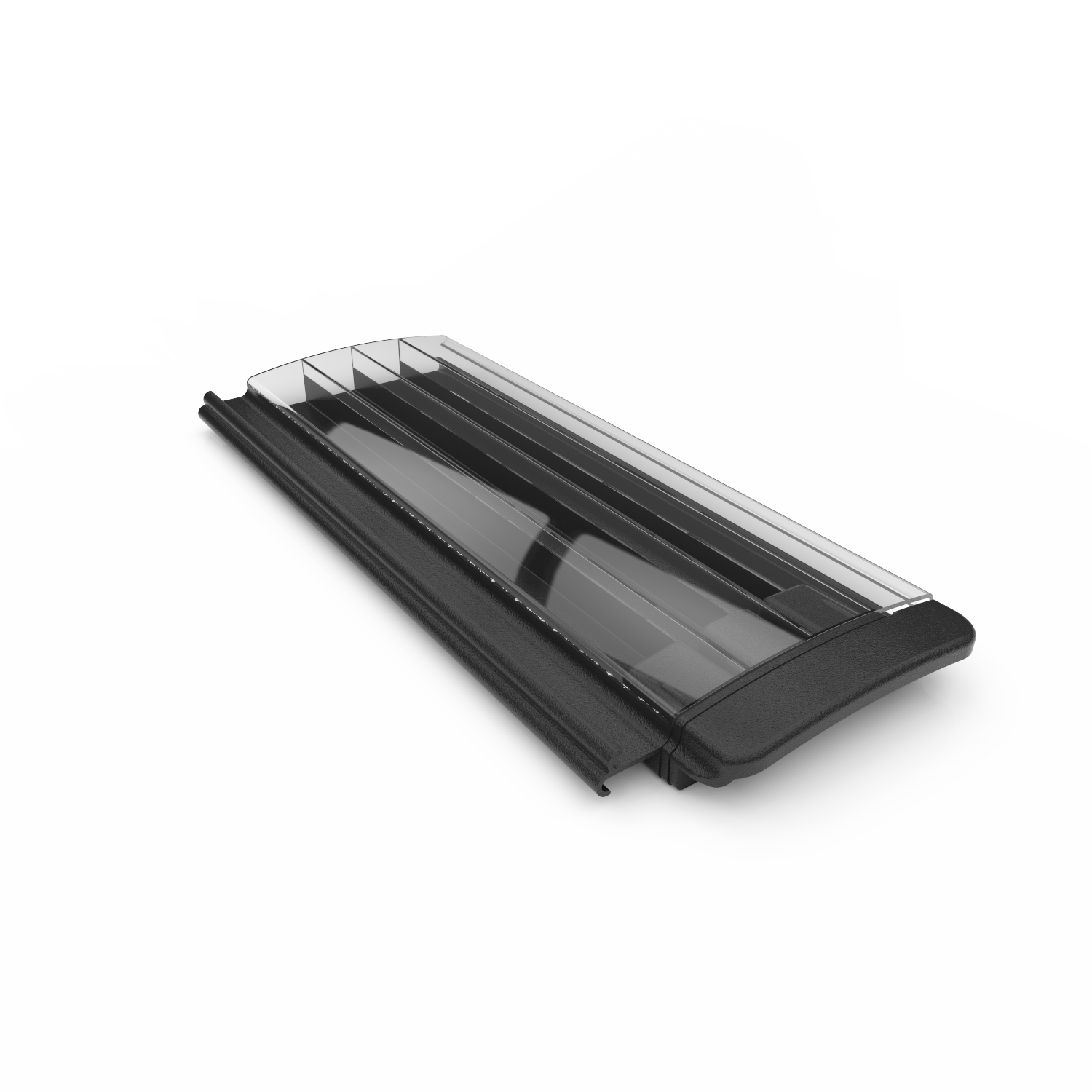

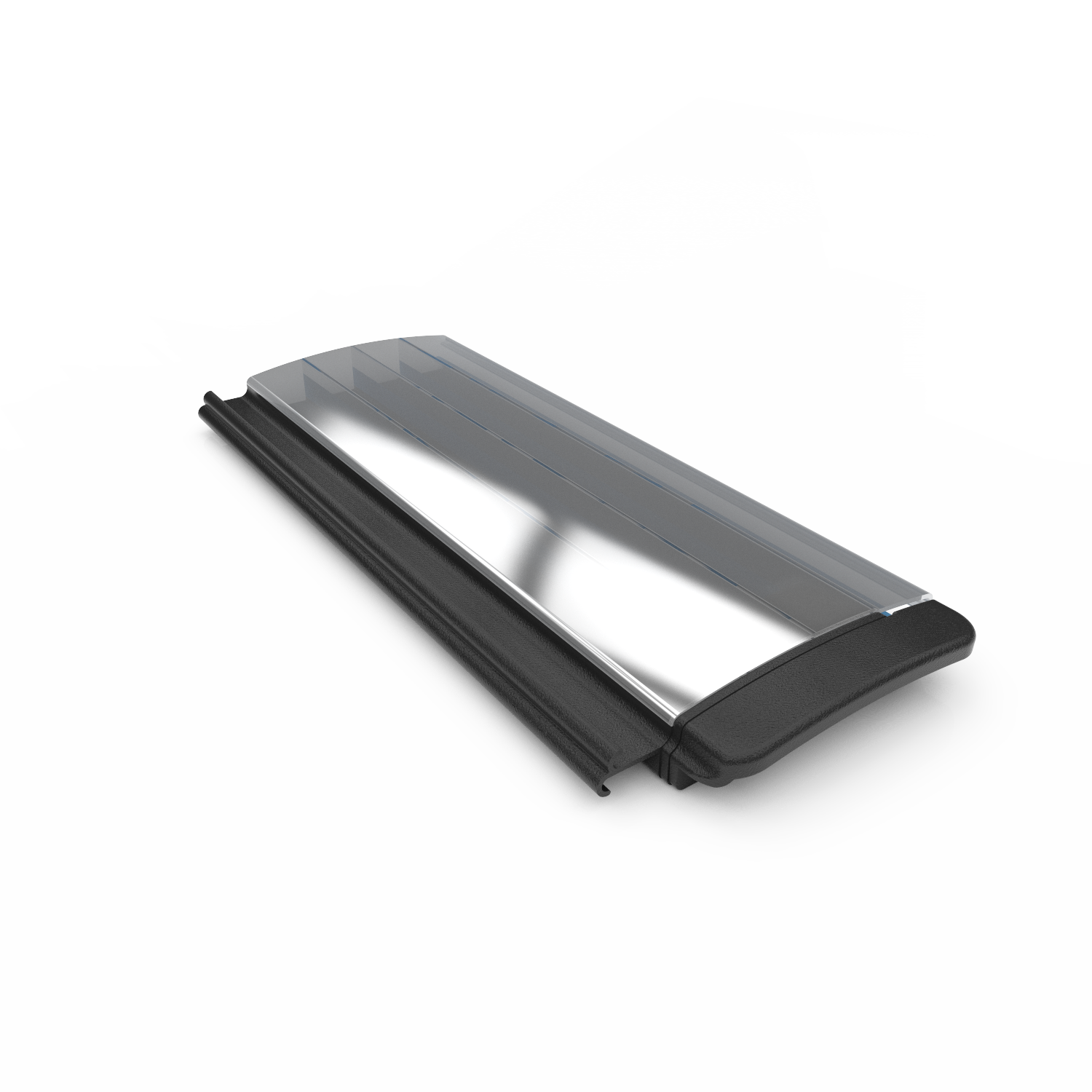

HF Cover Slats

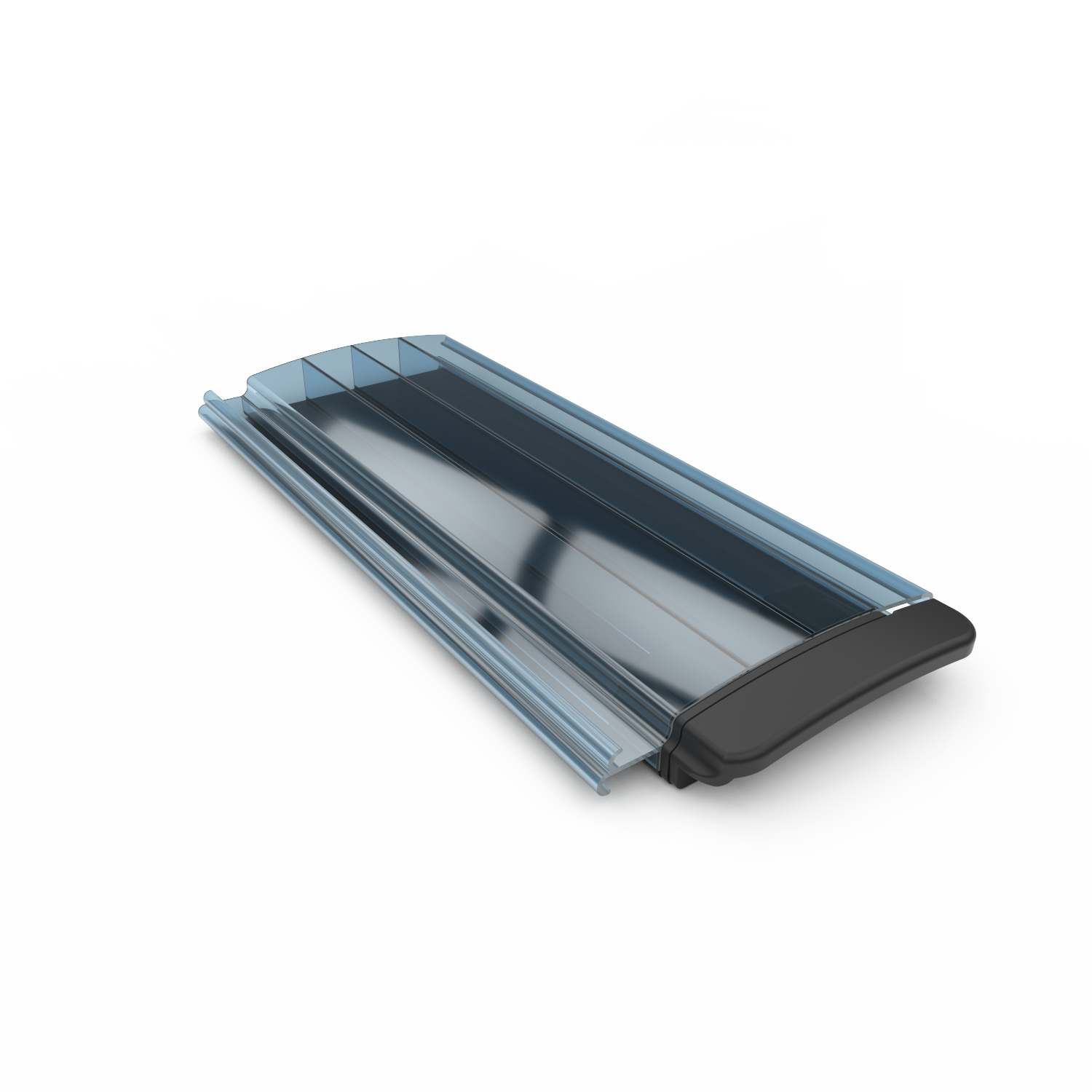

HeatForm offers 2 different slat types, the standard profile 60x14mm with 3 closed air chambers and the premium profile 67,5x16,5mm with 4 closed air chambers. The standard profile is available in PVC and polycarbonate. The premium profile is exclusively available in PC solar and aluminum look.

A high quality pool cover slat is characterised by its lifespan. The wall thickness of the profile is directly linked to the sustainability of the slat. Furthermore the quality of the raw material is decisive as well as the shape of the profile. The design of the slat determines to a large extent the stiffness and resistance to shock of the pool cover profile.

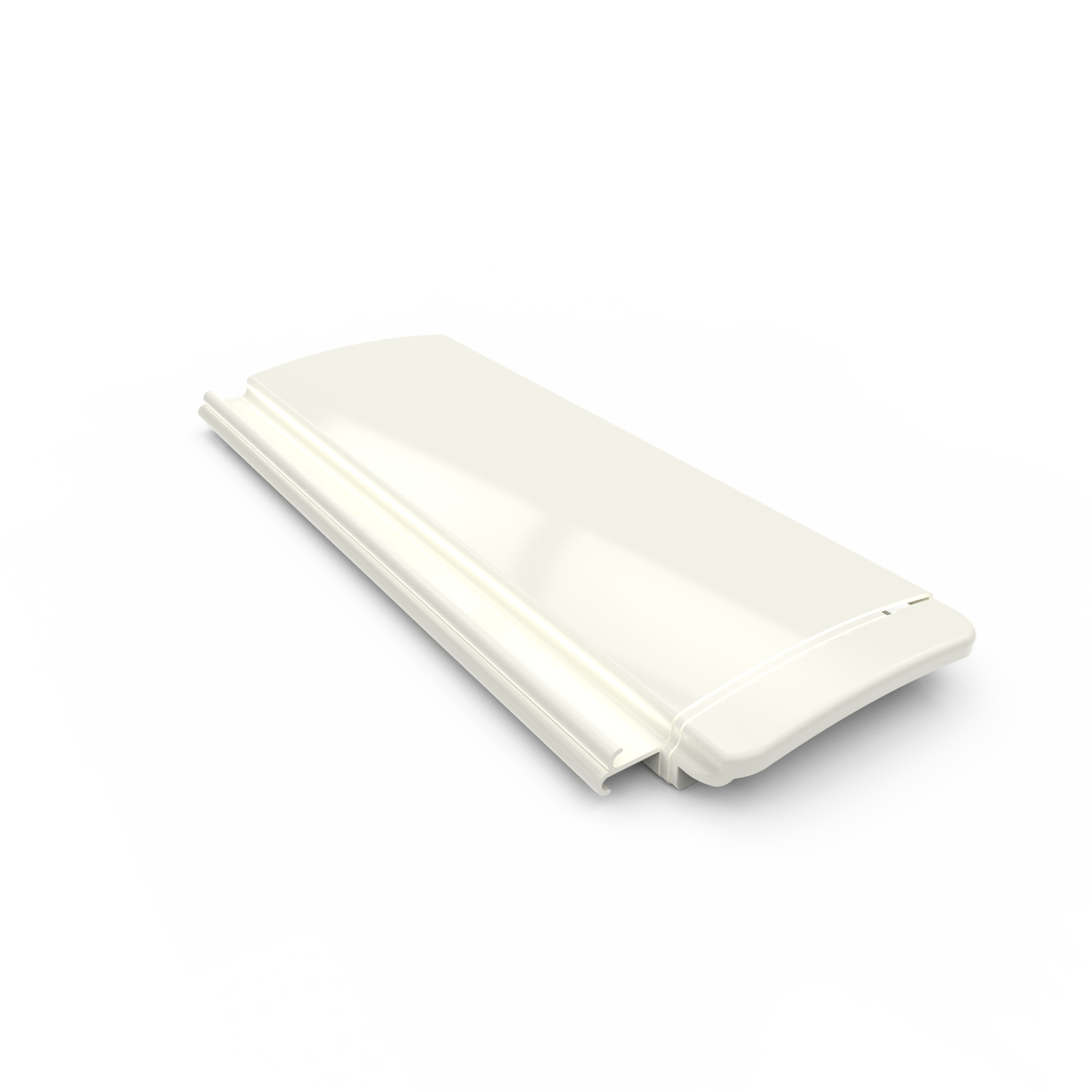

PVC White

PVC Beige

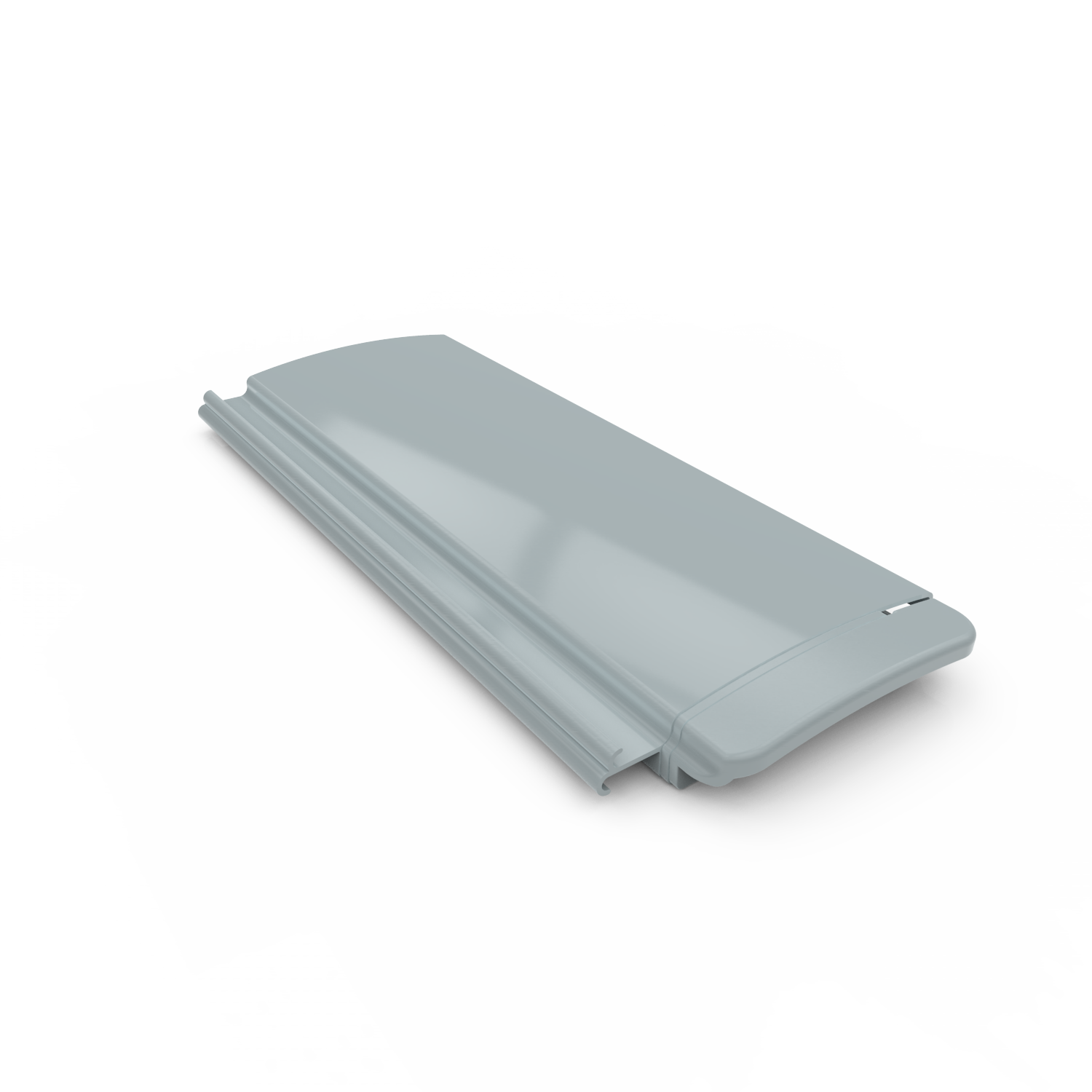

PVC Grey

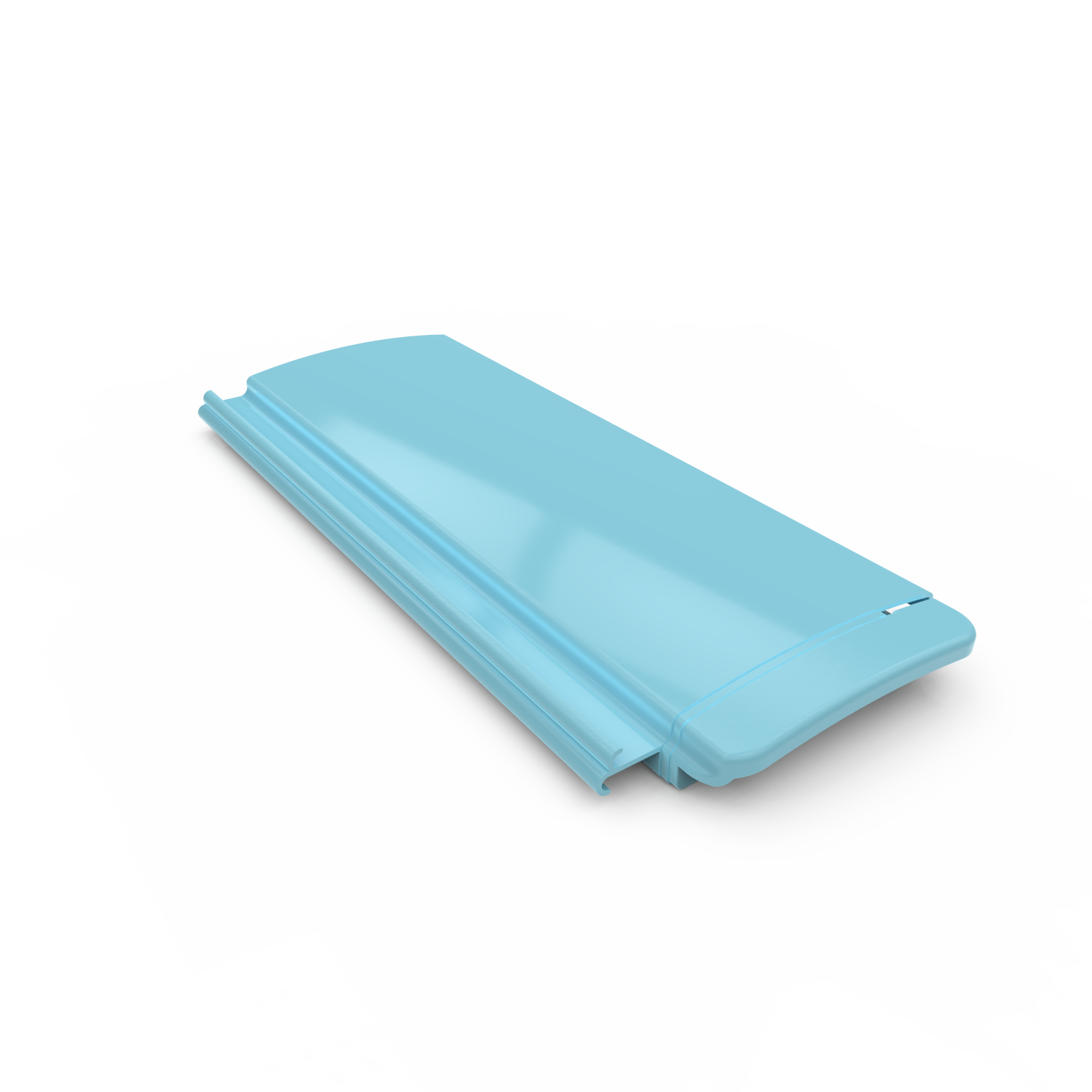

PVC Blue

PVC Solar (Tidal Only)

Polycarbonate Premium Blue

Polycarbonate Solar

Polycarbonate Aluminium